Are you in the process of choosing custom packaging for facial tools to sell for your beauty and personal care brand? Then you must have encountered challenges with product packaging customization. How should you choose the right packaging for different products?

Do you need simple packaging as a promotional item, or exquisite packaging for sale in supermarkets? Do you want your product to be noticeable enough on the shelf? And the consumers are surprised when they open the package? Or will you consider the convenience needs of consumers for their carrying? Different purchasing ways, sales channels, and usage will require different packaging methods.

As a company specializing in beauty and personal care products for over 10 years, we have accumulated a lot of experience in this area. In this article, we would like to share these experiences with you and hope to help you in your decision-making. Read on!

Outer Packaging

The outer packaging refers to the box we can see directly. In addition to product protection and convenient storage/transportation, outer packaging plays a greater role in increasing product sales. Well-designed and crafted outer packaging can enhance consumer preference and greatly increase product sales, especially in offline sales channels.

Cardboard Box

Printed paper box is the most common packaging in the household beauty instruments industry. In addition to meeting the basic packaging function, the cost and MOQ are not high. Home beauty products are usually lighter, and almost 80% of the products are packaged in printed paper boxes.

For the outer packaging box, you can not only customize the paper material, box structure and size, but also choose your favorite printing treatment effects, such as varnish, matte, lamination, bronzing, embossing, frosting, and more. Let’s make a detailed description here.

Box Shape / Structure:

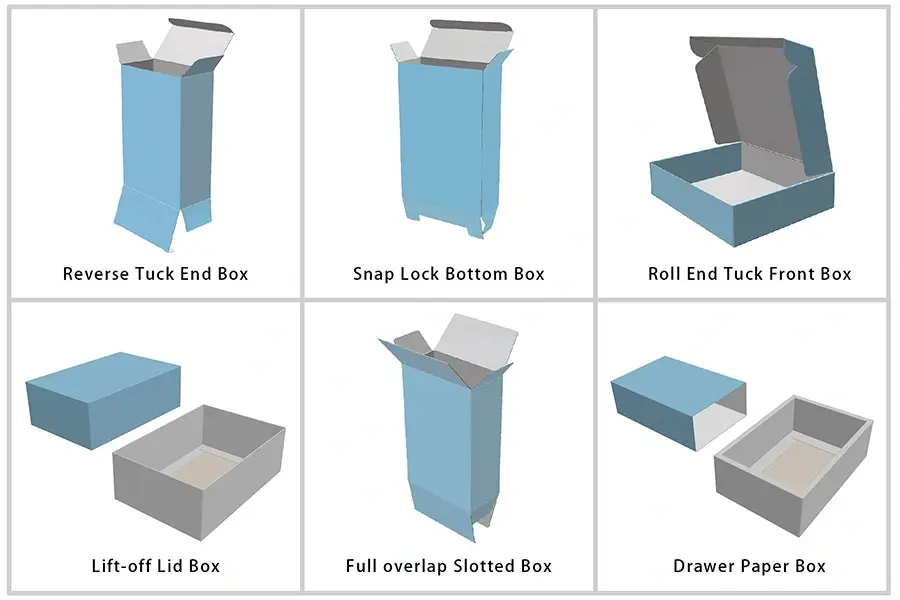

We can customize various styles of color boxes for the needs of customers, the most commonly used are the below styles, some special boxes are also available to be done.

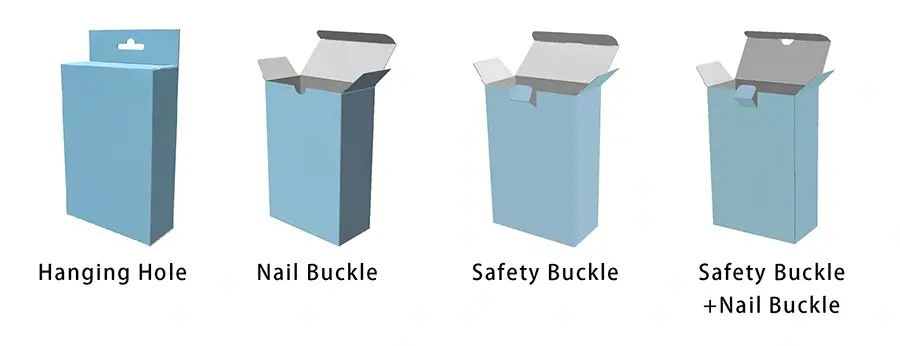

For different needs, we can also add various functional structures to the box for customers, such as hanging holes, nail buckles, safety buckles, and so on. Multiple functional structures can also coexist in one box. Below are some details for reference:

Hanging Hole: Applicable to products hung in supermarkets.

Nail Buckle:Easier to open box packaging.

Safety Buckle: If the whole package is heavy, the opening of the box may be easy to automatically disperse. At this time, a safety buckle structure can be added to this part, so that the box is not easy to automatically disperse, and the box as a whole will be flatter.

Cardboard Material

There are many different cardboard materials to choose from, below we only talk about a few of the most commonly used ones.

Single Coatd Paper

Single coated paper, as the name suggests, is the paper with a coating on one side, which is smooth and has good ink absorption for printing, while the other side is uncoated and matte, the same as ordinary printing paper (similar to A4 paper). It’s the most common material for color box printing.

The single coated paper is often used for single-sided printing of hang tags, hand bags, garment bags, exhibition bags, etc. It can also be used for double-sided colour printing, but the smooth side of the paper is much better than the plain side.

According to the thickness of the material, single coated paper can be divided into 250gsm, 350gsm, and 400gsm. Among them, 350gsm cardboard is the most commonly used material. 400gsm cardboard is used for the package of heavier products or the customer has higher protection requirements, and the cost is also higher.

Kraft Paper

Kraft, in German, means strength. Kraft paper is durable because of the good strength. It is made of the chemical pulm from the kraft pulp process. Therefore, the kraft paper is designed for the packaging products which need high strength and durability.

The unbleached kraft paper is brown. The kraft pulp is fully bleached to make the white kraft paper when whiteness, strength and resistance to yellow is important. The kraft paper is quite environment friendly, because it is 100% recyclable. And can be saft to be used for the food packaging, paper bag.

Specialty Paper

Specialty paper has a gorgeous appearance, which greatly increases the visual impact of the printed cosmetic paper box and cardboard gift box and gives people a deep impression. The specialty paper can have various colors, patterns, textures, and finish. The options are unlimited.

We once did a silver-coated paper package for one customer, you can click here for more details.

Finish Options

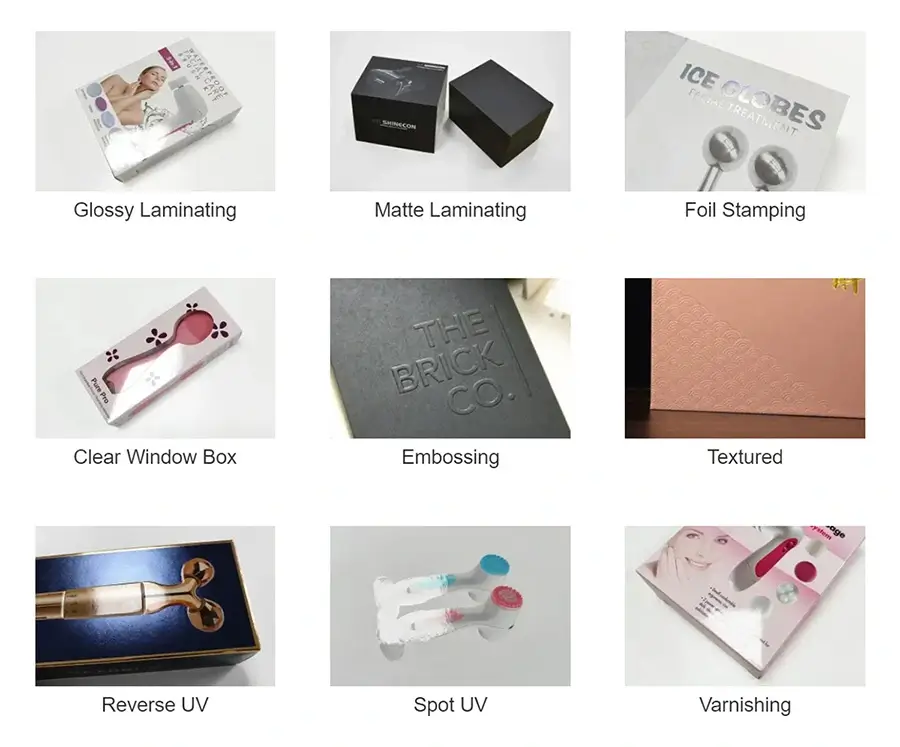

The printing finish adds a final touch to your package, turning your ordinary packaging boxes, bags, and manuals into extraordinary artwork. In addition, suitable finish options make the boxes water and moisture resistant, scratch-resistant, and increase the toughness of the boxes.

Finish options are generally used on the entire surface to achieve a special effect. Sometimes multiple finishes can be used simultaneously on one part of the box, such as gold stamping and embossing for the logo at the same time to achieve a three-dimensional gold logo effect.

Having a worth noticing finish for your packaging requires professional expertise. Our designer is with rich experience of over 5 years, and the printing finish we once did includes laminating, varnishing, UV coating (including all-over UV coating and spot UV coating), reverse UV, embossing, foil stamping, etc.

We will not talk more details here, just contact us if you have such requirements for your box.

Corrugated Box

The corrugated board has a three-layer construction, with a front liner (coated printable liner), a back liner (laminated with white/kraft paper for a flat surface), and a middle corrugated (increased strength and rigidity). It’s an excellent and ideal material for shipping boxes, cartons, and mailer boxes when strength and durability are needed. Also, it can be used to make various custom display boxes, stands, and trays.

The E flute corrugated printed box is one of the most popular used for beauty and personal care products packaging, with a thickness of 2.3mm at least. If the beauty instrument product with a heavier or larger package or the customer has a higher requirement for the firmness of the package. We recommend using this material.

The corrugated color box can be made into the same box shape/structure and finish as that of the single coated box.

Rigid Paper Box

Rigid paper boxes can greatly improve the overall texture of the product. They are made artificially glued, at a higher cost. Here, we just talk about 2 common boxes shape/structures in the beauty and personal care industry.

Box Shape / Structure:

Lift-off Lid Rigid Box

Also referred to as a telescope box, or detachable lid box, the lift-off lid rigid box has a separate top lid covering the bottom base fully or partially. The top lid can be easily lifted off the base tray.

The top lid and bottom base can be both printed. And normally, the two parts fit very closely, the protection of the internal products will be very good, but the disadvantage is that it is difficult to open the top lid sometimes, especially for tall boxes. We suggest to leave a nail buckle position at the edge of the top lid to solve this problem.

Hinged Lid Rigid Box

For the hinged setup box, the wraps and chipboards of the lid extend to form the base completely or partially. The book shape box is also a hinged lid box, there are some other common styles, like the clamshell rigid box, flip-top rigid box, and some popular presentation boxes.

Rigid Box Material:

Rigid boxes usually use three layers of composite paper.

In the picture above: Pink is the face paper;

White is the liner; Grey is the grey board

- The top layer is the face paper. Our main designs are printed on it. The face paper is usually made of the same material as the cardboard box, only a little thinner, various finishes can be added to the face paper.

- The middle layer is made of thick cardboard. This is the reason why the rigid boxes feel very hard and sturdy. Cardboard can be divided into white board and grey board, the former is more expensive than the latter.

- The innermost layer is lining paper. The purpose of adding the lining paper is to prevent the cardboard from being exposed and unsightly. Usually there is no printing on the lining paper. Of course, designs can also be made and printed on if required, this will increase the cost of the box.

Printing & Finish Options

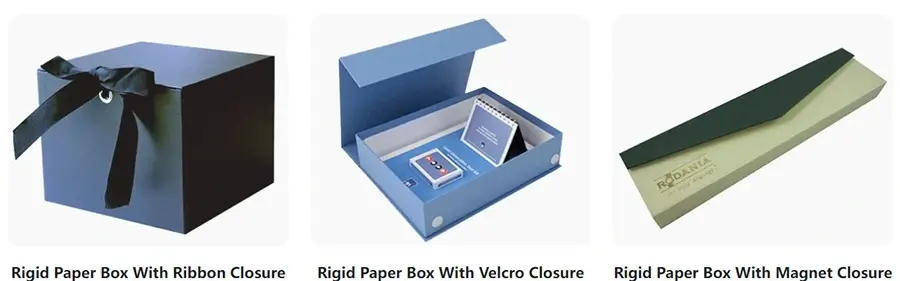

The rigid color box can be made into the same printing and finish as that of the single coated box. There are more finishes available for cardboard boxes because they can be made from a wider variety of materials, such as embossed paper, metallic paper, felt paper, and other specialty papers. In addition, rigid paper boxes can be closed in different ways, such as magnetic, ribbon, velcro, etc.

All these make the cost of the rigid paper boxes significantly higher than that of other printed boxes.

Plastic Box

Double Blister /Clamshell Packaging

Inner Packaging

Inner packaging refers to the packaging inside the outer packaging, which is in contact with the product and cannot be seen until the outer packaging is opened. The main function of the inner packaging is to fix and protect the product, and some can also play storage and supporting roles. Common inner packaging includes blister trays, die-cut trays (EVA, EPE, & High-density Sponge), etc.

Blister Tray

Die-cut Tray (EVA, EPE, & High-density Sponge)

EVA

EVA is a high-density material, free of plasticizers, non-toxic, biodegradable, and recyclable, environmentally friendly material. Compared with EPE and sponge, EVA has higher hardness, better cushioning performance, and a higher cost. Black and white are common on the market, other colors need to be customized.

EPE

EPE pearl cotton foam board is a common impact-resistant material, environmentally friendly and recyclable, non-toxic, softer than EVA.

Sponge

The sponge is the softest and lightest of the 3 materials. A high-density sponge is generally used as inner support for lighter-weight products. Some guests add a layer of flocking on the sponge to improve the packaging grade.

Plastic Bag

Plastic bag packaging is the simplest inner packaging, the product is directly placed in the plastic bag and then put into the color box. Common plastic bag materials are PE, PO, PP, PVC, OPP, CPE, etc.

Lower value and light products can use this packaging to save costs, such as manual face brushes, shampoo brushes, etc. The only function of a plastic bag is to prevent dirt or scratches on the product surface. Once it’s impacted, the protection mainly comes from the outer packaging.

Fabric Bag

If the consumer requires a product for portable or travel use, sellers will often add a flannel bag or organza bag to the packaging. They are usually included as an accessory, or the product is put into the bag and then into the packaging box. In addition, all three types of bags are usually supplied with a drawstring. Let’s briefly talk about them here:

Velvet Bag

The velvet bag’s hand-feeling is very good. According to the material, the velvet bag can be divided into velveteen, long velvet, double-sided velvet, suede, and so on. Of course, the cost of different materials will also be different. For mid-to-high-end beauty tools, such a bag is used to enhance the added value of products and customer experience. Examples, hot and cold skincare machines, multi-functional beauty instruments, etc.

With such a velvet bag, the product can be well protected when not in use and also easy to carry around. Velvet bags can be made in various colors, and your logo can also be printed on the bag.

Organza Bag

The organza bag is a translucent or fully transparent gauze bag with good durability and breathability. It is suitable to be a carrying bag and at a low cost. Some customers who purchase mid-to-low facial cleansing brushes will choose to add an organza bag, which has good air permeability and is convenient for volatilizing the residual moisture of the brush head. Organza bags can be made in various colors.

High-Grade Silk Packaging

Silk cloth is usually used in the inner packaging of high-end beauty products, which will greatly improve the product quality and brand image. Consumers will be psychologically satisfied after opening the package.

The silk packaging normally consists of two parts: the upper silk cloth and the inner tray below the silk cloth. There are too many kinds of silk fabrics to choose from, which can be selected according to the raw material, texture, appearance, and your main purposes. The inner tray is generally a supporting material such as EPE or high-density sponge.

The silk cloth and the inner tray need to be combined with glue or staples, which will spend a lot of labor, so the cost is high.

PP Box / Acrylic Box

For products with more accessories, PP box /Acrylic box packaging will be better than color boxes. In addition to being able to meet daily use and storage, they are not only waterproof but also impact-resistant, which also have better protection for the product and look more upscale. Generally, PP boxes/Acrylic boxes should be put into a color box then for retail.

The production of a PP box or acrylic box requires injection molds, and we generally provide the manufacturer’s existing box. Buyers can customize the color and material of the box, print your logo, or add stickers on the box. But if you need to design the shape of the box, a new mold needs to be opened, the mold-opening fee and the required MOQ will be high.

The End

In fact, in the beauty and personal care industry, there are many other special packaging materials and styles. This article is limited in space and only talks about some of the packaging customizations we often do.

Are you sourcing some beauty care tools products with customised packaging? Welcome to contact us. Feel free to leave your comments to share with us as well.

I don’t think any have doubts about how to choose the best packaging box after reading this article.

Thanks for your comments, Alex!